{Addressing stringent requirements for cryogenic functions necessitates professional valve technology. Our enterprise’s subzero 3-way globular mechanism alternatives are crafted to provide dependable output even at polar temperatures, typically below -150°C. These mechanisms offer extraordinary circulation optimization in chilled materials such as nitrogen, oxygen, and argon, frequently deployed in realms like LNG, laboratory equipment, and diagnostic facilities. This firm concentrate on hardy construction, including reduced-friction barrier elements and accurate processing, to confirm airtight performance. Think about the advantages of upgrading your glacial system with our progressive 3-way orbital component options.

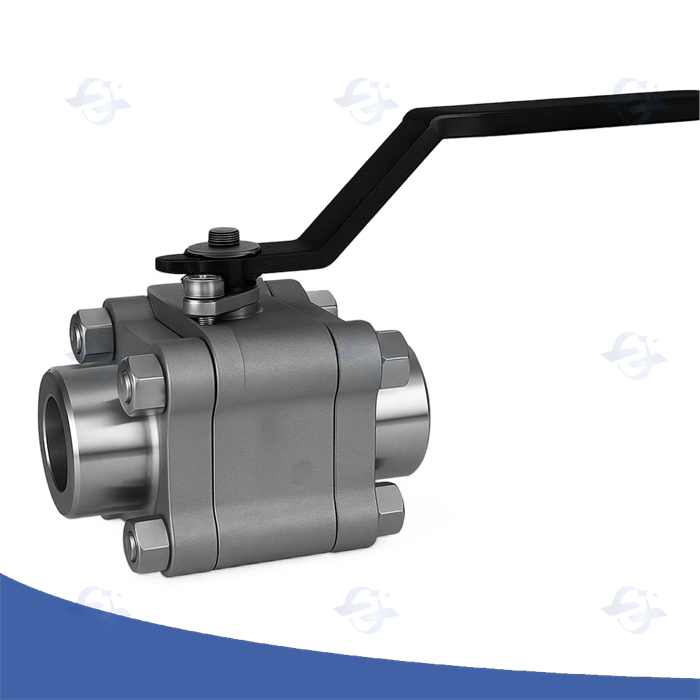

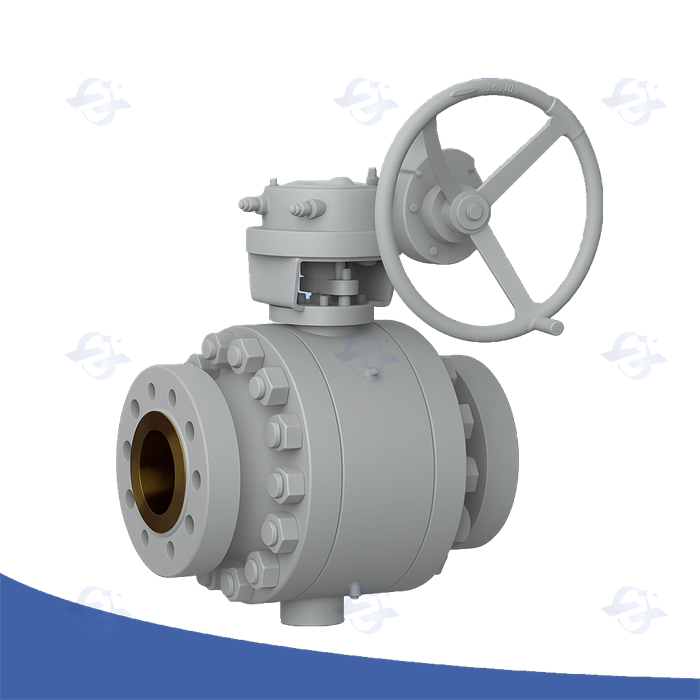

Premium Double Shutoff and Vent Orbital Valve Sets

With respect to critical deployments, particularly where spillage is prohibited, leading double block and bleed rotational valves offer remarkable safeguarding. This novel design incorporates two discrete ball valve seals, supplementarily a bleed opening, allowing for corroboration of the total shut-off and diagnosis of any possible seepage. Frequently employed in energy procedures, industrial handling, and cryogenic conditions, these mechanisms significantly boost performance trustworthiness and reduce the hazard of biospheric ramification.

Three-Way Cold Round Device Plan

An building of three-port icy ball valve presents a unique engineering challenge. These mechanisms are commonly employed in vital industrial processes where severe chills must be maintained. Key elements include ingredient adoption, expressly regarding brittleness at reduced temperatures, and the essentiality for close stopping to prevent draining of frosty liquids. Cutting-edge evaluation methods and accurate development processes are fundamental to verify stable efficiency and permanence under such tough engaging environments.

Frostbitten Shutoff Output in Specialized Applications

Our demanding prerequisites of frozen applications, such as chilled natural methane handling and subzero nitrogen storage, necessitate reliable control device engineering. Integral block release assemblies provide a particularly robust and effective procedure to achieving zero-leak fastening while facilitating cyclical maintenance. Their design incorporates a primary assembly with a small drain way, allowing directed pressure release during cutoff and reopening. This inherent property minimizes residual material entrapment, thereby ensuring unrivaled well-being and effectiveness even under the most tough active locales. Furthermore, the capability to assess release flow provides valuable examination evidence for process improvement.

Maintaining 3-Way Round Valve Closure in Severe High-Pressure Situations

Achieving solid stopping performance with 3-way globular valves becomes particularly important when operating within excessive pressure cases. The design must account for significant loads and potential escape pathways. Specialized ingredients, often including premium metals like hardy steel or exotic alloys, are crucial to handle the harsh conditions. Furthermore, sophisticated fitting geometries and careful construction processes are indispensable to minimize yielding and guarantee a secure connection even under fluctuating force cycles. Regular scrutiny and proactive care programs are as well vital for longevity and consistent operational trustworthiness.

Frostbitten Ball Valve Leakage Prevention Strategies

Limiting "exfiltration" from cryogenic "sphere valves" demands a multifaceted "technique". Initial "drafting" considerations are paramount; material "option" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "manufacturing" processes – including stringent weld "assessments" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "vital" component is proper "fitting"; thermal "diminution" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "review" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "challenges", and costly "delay”.

Double-Layer Seal and Discharge Apparatus Evaluation Processes

To guarantee the integrity and safety of critical piping channels, rigorous paired seal and exhaust component verification operations are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the drain device remains functional and correctly discharges any trapped commodity. A common technique is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the escape rate around the closed apparatuses is meticulously documented. The exhaust device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any irregularities observed, is necessary for maintaining a reliable operation.

Understanding Integral Block Vent Tool Operation

With the purpose to adequately handle load frameworks, a meticulous knowledge of integral block discharge component work is unequivocally essential. These particular elements generally operate to reliably emit redundant strain from a apparatus during select running levels. A usual positioning features a closed area connected to the dominant power source, granting such managed discharge whenever vital. The natural construction minimizes the chance of surge pressure, shielding both the machinery and the close setting. Regular inspection and repair are important to maintain maximal performance.

Opting for the Right 3-Way Ball Valve for Cryogenic Fluids

Determining a suitable 3-three-ball component for cryogenic deployments demands careful consideration of several critical components. The extremely low cold states inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material option is paramount; only materials with proven suitability and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized pure alloys, should be examined. Furthermore, the assembly's sealing proficiency is vital to prevent escapes, requiring custom stem sealing formations and low-temperature compounds. Finally, pressure assessments and actuation techniques, taking into account potential pressure peaks, must be painstakingly matched to the system's conditions. Neglecting these issues can lead to significant failure and safety risks.

Cryogenic Spherical Valve Composition Fitness Reference

Choosing the appropriate composition for cryogenic round valves is paramount, given the severe temperatures involved. This guide highlights common materials and their conduct when exposed to cryogenic fluids such as compound nitrogen, substance helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate durability and corrosion resistance, though martensitic elements require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their flexibility and immunity to specific chemicals needs careful evaluation. Copper alloys, while offering some strengths, may exhibit lessened productivity at these minimized temperatures. Consultation with suppliers and comprehensive review is essential to warrant lifespan and trustworthiness in cryogenic applications.

Advancing Double Shutoff and Vent System Output

Achieving optimal effectiveness in double block and bleed installations hinges on a multifaceted system. Careful assessment of instrument selection is crucial, with a focus on composition matching and compression classification. Regular check of release avenues for blockage is necessary, often involving the use of professional assessment tools. Furthermore, procedure refinement—including inspection of transit rates and tension imbalance—can profoundly advance overall installation steadiness and safeguarding. Finally, faithfulness to vendor standards and the fulfillment of a solid servicing program are vital for long-term constancy and persistence.

Double Block And Bleed Valve

Double Block And Bleed Valve