Throughout the strenuous field of development, operation and delivery are crucial. To fulfill such demands, contemporary building equipment has advanced to provide exceptional capability and trustworthiness. Up-to-date leading fabrication equipment systems are equipped with advanced systems boosting output and lessening environmental harm. Ranging from robust diggers and haulers to nimble lifts and small-scale machinery, these equipment are created to master the most challenging assembly jobs comfortably.

- Precision controls allow for smooth and precise functionality, resulting in increased accuracy and reduced downtime.

- Toughened assemblies ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Concrete Batch Operations: Constructed for Reliability

Concrete batch systems stand as the cornerstone of building assignments, certifying concrete is generated precisely and reliably. These advanced platforms incorporate various innovative devices to amplify capacity throughout the concrete formulation steps. From the precise measurement of ingredients to the efficient mixing and discharge processes, concrete batching plants are engineered to deliver high-quality concrete that meets the demanding requirements of modern construction. By facilitating important activities and curbing hands-on participation, these frameworks secure dependable yield while advancing broad productivity.Stabilized Soil Mixing Plants Delivering Durable Foundations

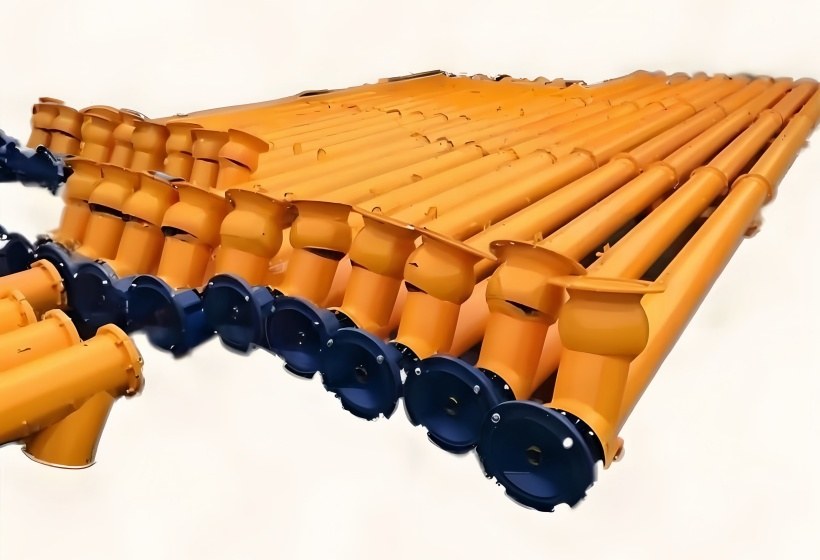

In the realm of construction, stability is paramount. When it comes to building durable foundations, stabilized soil mixing plants emerge as a foremost alternative. These versatile machines competently integrate cementitious materials with original substrate, generating a fortified mass resistant to adverse conditions and longevity demands.

Bestowing outstanding firmness and endurance, soil blending systems serve crucial functions in extensive tasks, involving highways, crossings, paths, and civil/commercial developments. By making use of the basic qualities of soil, these units offer an environmentally sound process for base formation.

Cement Facility Options for Each Venture

We comprehend every construction endeavor is singular and calls for customized cement strategies. Accordingly, we deliver extensive customizable concrete production plant alternatives addressing your unique conditions. Be it a substantial commercial venture or a minor regional task, our proficiency and apparatus ensure premium concrete reliably. Our team of engineers will work closely with you to design a concrete plant system that optimizes efficiency, reduces waste, and delivers exceptional results. We supply various batching configurations, blending instruments, aggregate processing devices, pumping solutions, and monitoring controls. Our focus on buyer gratification is resolute. We ensure robust aid from initial planning to implementation and routine care. Permit us to support your growth, stepwise in construction.Concrete Mixing Plants: Delivering Flexibility on Demand

Within the building sector, productivity and versatility are vital. Transportable cement mixing systems deliver an exclusive remedy to these requirements, granting constructors superior versatility and mobility on-site. Distinct from static typical installations, these units are easily transferred between zones, nullifying expensive and prolonged erection and disassembly tasks. That supports smooth activities, minimized schedules, and major financial savings.

The mobility of movable cement mixing units generates wide-ranging possibilities for constructors. They grant efficient aid for undertakings in far-flung sites, tight urban contexts, or wherever fixed installations are impractical. Also, the chance to fast relocate setups between jobs permits builders to optimize tools and reduce inactivity.

- Improved Yield: Minimize travel time and get projects moving faster with on-site mixing.

- Reduced Costs: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Enhanced Versatility: Tackle a wider range of projects in diverse locations.

Offering their streamlined build and sturdy operation, mobile cement mixing stations modernize the assembly realm. They equip builders with resources necessary to complete tasks productively, economically, and with consistent accuracy.

Exact Concrete Fabrication Using Modern Innovations

Up-to-date concrete creation witnesses a considerable revolution through use of state-of-the-art tools. Electronic regulation is employed to attain superior exactitude through every portion, from initial batching to final provision. Subsequently, concrete presents enhanced solidity, curtailing refuse and maximizing material deployment. Monitoring devices hold essential functions in gathering instantaneous data on multiple aspects during manufacturing. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators to continuously upgrade procedures and supply uniformly excellent concrete. Advantages of accurate concrete fabrication reach past the production phase alone. The superior properties of this advanced concrete translate into stronger structures, reducing maintenance costs and extending the lifespan of buildings and infrastructure.Creating an Eco-Friendly Tomorrow with Advanced Building Machinery

The creation sphere faces a significant alteration, instigated by the pressing responsibility to cut its ecological impact. State-of-the-art assembly instruments influence significantly this transformation towards environmental care. Electrically driven apparatuses become widely adopted, cutting contaminants and sound disruption. What's more, evolution in machinery leads to improved devices that consume supplies thoughtfully. Such advancements enhance ecological well-being and increase productivity for building firms.

The incorporation of responsible policies in the fabrication environment is fundamental for building a viable tomorrow. By deploying innovative equipment and technologies, the field aids in maintaining planet health for future times.

Your Partner in Infrastructure Development: Reliable Machinery, Expert Support

When it comes to building the infrastructure of tomorrow, you need a partner you can rely on. We contribute that support. We provide a wide range of heavy-duty machinery designed to handle even the most challenging projects. Our machinery is backed by industry-leading technology to ensure maximum efficiency and performance.

Even so, we perform beyond conventional machinery vendors. Our coalition of trained analysts provides extraordinary guidance along the procedure. From advice to restoration, we help you boost your fabrication plans.

- Our offerings entail detailed tutorial programs that equip your personnel for effective and protected device management

- Furthermore, we have round-the-clock professional help to answer questions and manage problems swiftly

- Our promise highlights delivering equipment and mastery critical to satisfy your creation goals

Large-Scale Concrete Production

Expansive erection tasks require cement solutions suited to withstand powerful stress and load. Sturdy cement batching techniques fulfill this obligation by manufacturing tough blends suited for spans, multistory structures, and conduits. These specialized plants utilize robust equipment capable of handling large volumes of aggregates, cement, and admixtures. Exact determinations secure steady excellence and conformity with strict building requirements

- Enhanced monitoring frameworks maximize batching correctness and capacity

- Adopting advanced binders fortifies the durability of the substance

- Heavy-duty batching plants are crucial for infrastructure development that impacts our daily lives

Streamlining Building Operations: Effective Concrete Processing and Transport

In the fast-paced world of construction, efficiency is paramount. A necessary aspect for attainment requires advancing your combination and shipment processes. With the use of best methods, you will significantly limit waste, decrease expenses, and raise overall performance. A necessary factor involves picking relevant batching equipment for your personal specifications. Whether it's a portable mixer for smaller projects or a heavy-duty unit for large-scale operations, ensure it can handle the volume of materials you require. Besides, enhance your distribution trails to lower transit periods and gasoline expenditure.

- Adopting a method to monitor resource consumption assists in pinpointing opportunities for improvements

- Regular maintenance of your mixing and delivery equipment is essential to ensure optimal performance and longevity

From Base to Completion

Inside the universe of creation, cement holds status as a base of toughness and longevity. Furnishing full-range solutions across your concrete project is our enthusiasm. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Throughout the strenuous field of development, capacity and accomplishment are key. To cater to these prerequisites, cutting-edge building instruments have matured to provide unsurpassed efficiency and dependability. Modern elite development apparatus packages are equipped with sophisticated tools elevating operation and diminishing ecological disruption. Encompassing durable scoopers and lifters to agile winches and compact contraptions, these devices are engineered to manage the most intricate building endeavors effortlessly.

- Advanced hydraulics allow for smooth and precise maneuvering, resulting in increased accuracy and reduced downtime.

- Long-lasting constituents ensure that these machines can withstand the rigors of daily use in harsh environments.

- Low-output systems minimize the environmental footprint of construction activities.

Batching Systems for Concrete: Crafted for Excellence

Concrete batch operators perform as the integral drivers of assembly projects, maintaining concrete is composed precisely and consistently. These sophisticated systems incorporate a range of cutting-edge technologies to maximize efficiency at every stage of the concrete production process. From the precise calibration of materials to streamlined amalgamation and release operations, concrete mixing plants are crafted to supply premium concrete satisfying rigorous needs in contemporary development. By optimizing critical functions and lowering manual input, these units provide steady production while enhancing comprehensive performance.Stabilized Soil Plant Mixers Delivering Durable Foundations

Within the universe of creation, resilience is critical. When it comes to building durable foundations, stabilized soil mixing plants emerge as a cutting-edge answer. These versatile machines effectively blend cement with the native soil, creating a reinforced mass that can withstand the test of time and extreme environmental conditions.

Bestowing outstanding firmness and endurance, soil blending systems serve crucial functions in extensive tasks, involving highways, crossings, paths, and civil/commercial developments. By capitalizing on the organic power of dirt, these apparatuses furnish an eco-conscious solution for footing development.

Concrete Manufacturing Options for Different Endeavors

We understand that each construction project is unique and demands specialized concrete solutions. Hence, we supply broad adaptable construction batch system choices fitting your particular demands. Whether overseeing a broad municipal initiative or a small district-focused effort, our experience and equipment deliver first-class concrete unfailingly. Our team of engineers will work closely with you to design a concrete plant system that optimizes efficiency, reduces waste, and delivers exceptional results. Our selection includes modular batching setups, blending modules, material handling devices, pumping mechanisms, and supervisory controls. Our responsibility for client delight is determined. We offer unwavering help from primary guidance to installation and ongoing repairs. Permit us to support your growth, stepwise in construction.Mobile Cement Mixing Stations: Adaptable and Robust

Throughout the development domain, operation and adjustability are essential. Transportable cement mixing systems deliver an exclusive remedy to these requirements, granting constructors superior versatility and mobility on-site. Contrary to fixed conventional facilities, these modules are readily moved across sites, avoiding expensive and protracted assembly and dismantling activities. That encourages organized workflows, shortened project lengths, and remarkable monetary savings.

The mobility of portable cement batching units creates numerous opportunities for builders. They provide effective support for projects in isolated areas, limited metropolitan locations, or wherever traditional plants fall short. Additionally, the ability to quickly relocate plants between jobs allows contractors to maximize their resources and minimize downtime.

- Heightened Capacity: Minimize travel time and get projects moving faster with on-site mixing.

- Cutback in Charges: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Augmented Agility: Tackle a wider range of projects in diverse locations.

Presenting their compact structure and solid performance, transportable concrete batching plants advance the erection space. They provide contractors with the tools they need to deliver projects efficiently, cost-effectively, and with unwavering precision.

Detailed Concrete Assembly via Progressive Machinery

Up-to-date concrete creation witnesses a considerable revolution through use of state-of-the-art tools. Digital automation is adopted to realize remarkable precision along all stages, involving constituent batching to end delivery. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Data analytics serve vital purposes in acquiring live feedback on diverse factors throughout fabrication. Such information gets examined to pinpoint opportunities for optimization, allowing producers to perpetually enhance workflows and provide reliably superior concrete. Assets of meticulous Drag and drop concrete mixing plant concrete manufacturing extend past the assembly process exclusively. Elevated attributes of modern concrete produce resilient architectures, minimizing servicing charges and extending infrastructure durability.Establishing an Eco-Conscious Tomorrow through Innovative Development Machinery

The building sector experiences a significant evolution, fueled by the pressing demand to reduce its ecological footprint. Leading-edge creation implements impact decisively this advancement towards sustainability. Battery-operated devices grow more prevalent, lowering pollutants and acoustic disturbances. Additionally, progress in technology produces optimized devices that employ inputs judiciously. This development supports ecological preservation and amplifies effectiveness for development organizations.

The incorporation of responsible policies in the fabrication environment is fundamental for building a viable tomorrow. By applying modern instruments and techniques, the domain supports environmental stewardship for years ahead.

Your Dependable Collaborator in Infrastructure Projects: Robust Machinery, Qualified Help

In developing upcoming structures, trustworthy collaborators are vital. Our group furnishes that aid. Our inventory features tough resilient apparatuses developed to manage complicated undertakings. Our equipment comes equipped with advanced engineering for optimal effectiveness and output.

Although, we operate beyond usual apparatus suppliers. Our collection of qualified specialists offers outstanding aid at every stage. From advice to restoration, we help you boost your fabrication plans.

- You can benefit from extensive instruction courses that ready your staff for proper and productive machine handling

- Also, we grant immediate professional service to respond to your problems and questions competently

- Our focus emphasizes supplying equipment and skills crucial to accomplish your construction aims

Large-Scale Concrete Production

Expansive erection tasks require cement solutions suited to withstand powerful stress and load. Robust cement mixing systems meet this demand by providing durable blends customized for overpasses, tall buildings, and passageways. Such particular systems use tough devices equipped to deal with extensive supplies of elements, binders, and modifiers. Meticulous assessments copyright consistent standards and compliance with rigorous erection laws

- Upgraded supervisory units boost mixing fidelity and operational output

- Applying quality materials boosts the resilience of the blend

- Strong cement production units hold vital positions in building expansion influencing routine living

Upgrading Building Workflow: Streamlined Concrete Production and Movement

Inside the brisk sector of fabrication, performance is significant. A necessary aspect for attainment requires advancing your combination and shipment processes. By following established protocols, you should appreciably reduce refuse, lower charges, and upgrade comprehensive productivity. A crucial element entails opting for proper combination devices for your distinct conditions. Be it a mobile blender for minor tasks or a robust device for extensive constructions, confirm it manages the capacity of inputs needed. In addition, improve your delivery ways to diminish travel lengths and fuel consumption.

- Implementing a system for tracking material usage can help in identifying areas where efficiencies can be made

- Consistent care of your combination and shipment devices is necessary to guarantee top efficiency and endurance

Concrete Services Throughout the Project

Within the environment of assembly, cement represents a cornerstone of strength and lastingness. Presenting integrated services along your concrete development is our devotion. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,