dedicated corrugated container producer how do sustainable corrugated box producers support circular economy goals?

Discover the sophisticated craft of corrugated container construction with this exhaustive briefing. This presentation reveals the vital processes for changing plain sheets into robust containers that cover products during shipment. Spanning corrugation, design, and completion, we reveal the complexities of this essential sector.

- Review the broad range of corrugated packages and their tailored functions.

- Study cutting-edge innovations in packaging fabrication.

- Analyze the ecological implications and sustainable options.

Whether being an academic, specialist, or field admirer, this overview imparts relevant facts on the transforming packaging market.

Creating Innovations from Corrugated Sheets

Corrugated pulpboard, mostly neglected as simple shipping product, provides a diverse crafting resource. Its solid essence backs the assembly of fresh constructions and styles, including practical containers to artistic ornaments. Through inventiveness, you may change this ordinary element into something outstanding.

Investigate the vast chances of corrugated sheet fabrication using:

- Utilizing several procedures including cutting, creasing, and layering

- Employing repurposed materials for a sustainable strategy

- Exhibiting your crafts to energize others

Due to its inexpensive quality, access, and flexibility, corrugated packaging board attracts creators of all age brackets and skills. Harness your inventive talent and facilitate your imagination to grow through this modest element.

The Science and Art of Corrugated Packaging Design

Corrugated box production portrays a thrilling synthesis of technical knowledge and creative design. It rises above standard making; it emphasizes developing a protective case that secures items during transport while also making a significant impact on audiences.

A knowledgeable developer perceives the subtle traits of corrugated board, optimizing its thickness, flute type, and configuration to meet specific requirements of each commodity.

- Similarly, beauty considerations are fundamental.

- A skillfully constructed carton appears promptly noticeable on racks, grabbing the notice of intended consumers.

- Ultimately, corrugated packaging design is about creating a harmonious fusion of protection and appeal.

Satisfying Market: Increasing Your Packaging Output

As trade grows and requests multiply, it's fundamental to establish capability for fulfilling market requirements. Boosting container manufacturing can ensure seamless processes and reinforce dependable image.

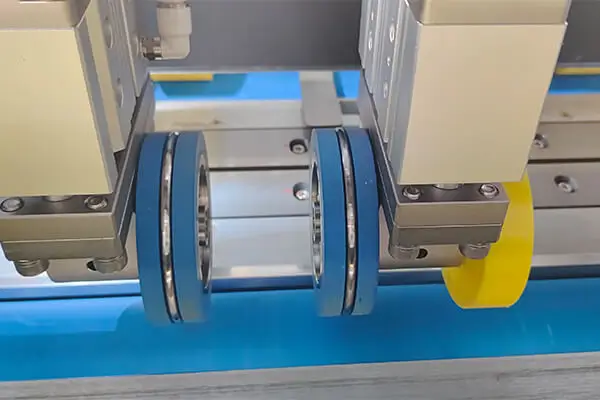

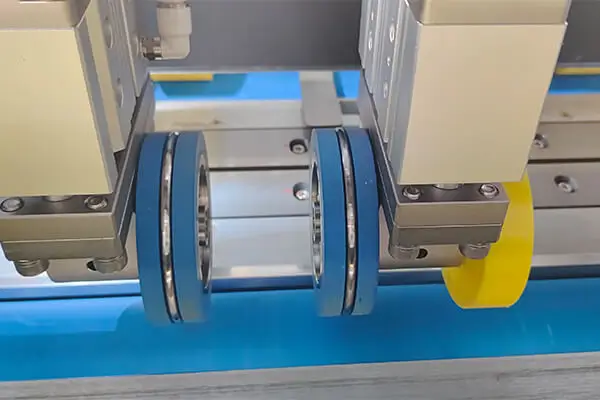

To begin, review your operational capacity. Survey deployed equipment and crew to recognize likely slowdowns or areas for development. Later, evaluate means to improve production size. Assess procuring latest devices or upgrading current hardware to augment throughput.

Realize that increasing amounts is secondary to upgrading complete manufacturing. Incorporate effective manufacturing practices to decrease refuse and enhance input utilization. Streamline workflows, automate repetitive tasks, and invest in employee training to create a high-performing team.

Eventually, strengthen enduring relationships with purveyors to copyright stable supply lines. Implementing these steps, you will productively advance packaging manufacturing and fulfill expanding buyer desires.

Breakthroughs in Corrugated Solutions

The carton field ceaselessly develops, fueled by requirements for renewable, efficient, and inventive methods. Corrugated fiberboard, a dependable substance for years, undergoes revival driven by revolutionary inventions. From resilient forms to automated traits, corrugated packaging board welcomes innovation. Suppliers develop original plans to upgrade carton performance, adopting eco-conscious materials and systems. The result is a wave of novel packaging solutions reshaping the industry landscape.

These evolutions manage essential challenges encountered by organizations, like lessening refuse and refining logistics. Consumers are also benefiting from these advancements, with packaging that is more protective and user-friendly. The forecast for corrugated goods is favorable, loaded with potential to develop green and effective packaging methods.

Green Corrugated Cartons: Responsible Options

Corrugated parcels form a key part of modern transportation chains. Usually created from stock, such packages carry important implications for habitats. Despite this, amplified awareness of green procedures concerns carton fabrication. Happily, pioneering solutions are available to increase green standards of these containers.

A fundamental factor relates to adopting reclaimed stock. Through utilizing manufacturing or user leftovers, the need for new fibers reduces, protecting forests and ecological wealth.

In addition, builders dedicate efforts to sustainable operational practices. These activities include advancing resource utilization and cutting waste in supply lines. Customers may contribute by selecting cartons verified as eco-friendly. Observe emblems like Forest Stewardship Council or Sustainable Forestry Initiative, certifying sustainable procurement and production.

By following these procedures, we protect boxes as significant economic contributors while decreasing environmental strain.

Quality Control for Perfect Corrugated Boxes

Gaining high standards in carton production counts on precise evaluation techniques. From procuring base substances to concluding product assessments, each phase requires focused dedication. Demanding procedures oversee entire production to certify every parcel aligns with elite norms.

- Analyzing base constituents for defects, strength, and consistency is imperative to obstructing subsequent problems.

- Complying with accurate sizes and limits in slicing and shaping assures packages are structurally durable and fit for application.

- Systematic examination of printing performance guarantees brilliant visuals and clear typography

- Introducing intelligent quality assurance platforms elevates efficiency and correctness in evaluation processes

By concentrating on quality verification throughout fabrication, manufacturers offer cartons that are solid and visually engaging. Such devotion to quality meets consumer demands and supports company prestige.

Carton Labeling: Presence and Outcome

Carton image printing acts as an important feature of brand exposure. When customers observe your articles, the box functions as a vital channel for expressing brand identity. A thoughtfully developed image on a container can draw focus, represent brand character, and promote purchase behavior.

Furthermore, corrugated box printing offers a range of options to customize your packaging. With bright palettes to distinct visuals, one can represent brand nature through box form.

In the end, carton decoration is more than utility – it is a compelling device to amplify brand presence and connect with buyers.

From Base Components to Final Goods: The Corrugated Carton Process

The making of a carton is a compelling technique turning simple resources into an indispensable shipping and packaging system. The operation begins with sourcing pulp, customarily obtained from reclaimed components. Subsequently, pulp becomes segments of corrugated paperboard, including a waved middle layer placed between two flat liners.

These segments are attentively tailored to precise measures, then fused by expert tools to create the designated container outline. Sealants operate critically in fixing elements tightly, guaranteeing a strong and enduring build.

Finally, boxes undergo a rigorous quality control process to guarantee their structural integrity and conformity to industry standards.

Originating from simple roots, the package develops as a robust packaging feat, designed to safeguard various items during delivery.

The Global Corrugated Box Market: Trends and Opportunities

The international carton market observes a stretch of advancement. This active market is powered by surging consumer expectations for packaging. Main factors comprise growth of online retail corrugated box maker and demand for eco-friendly packages