cutting-edge box manufacturing enterprise how do creative cardboard packaging designers boost brand recognition?

Discover the sophisticated craft of corrugated container construction with this exhaustive briefing. The guide uncovers the crucial measures in converting basic materials into durable cartons that guard goods throughout transport. Spanning corrugation, design, and completion, we shed light on the nuances of this crucial market.

- Identify the varied models of corrugated carriers and their special uses.

- Analyze advanced methods in container creation.

- Analyze the ecological implications and sustainable options.

If you are a scholar, practitioner, or market follower, this explanation conveys meaningful expertise on the fluctuating container manufacturing area.

Developing Designs Using Corrugated Material

Corrugated carton board, often unappreciated as basic packing item, works as a functional crafting element. Its durable quality enables the formation of innovative shapes and patterns, spanning useful organizers to fanciful embellishments. Using imagination, you have the power to modify this familiar fabric into everything remarkable.

Review the broad scope of corrugated carton board making by:

- Adopting various techniques such as slicing, bending, and layering

- Using recycled content for an environmentally sound method

- Demonstrating your models to uplift others

Thanks to its budget-friendliness, approachability, and multifunctionality, corrugated paperboard fits creators of all generations and expertise. Discover your creative potential and let your imagination take flight with this unassuming substance.

The Combination of Functionality and Flair in Corrugated Box Design

Corrugated box production portrays a thrilling synthesis of technical knowledge and creative design. It outperforms typical crafting; it prioritizes producing a defensive enclosure that protects merchandise in shipment while also making a noteworthy impression on purchasers.

A knowledgeable developer perceives the subtle traits of corrugated board, optimizing its thickness, flute type, and configuration to meet specific requirements of each commodity.

- Similarly, beauty considerations are fundamental.

- A professionally made package is rapidly discernible among products, pulling the sight of interested buyers.

- At its core, container crafting blends defense and allure.

Catering Demand: Elevating Your Carton Creation

With flourishing trade and rising orders, it's essential to confirm ability to satisfy buyer expectations. Growing carton creation may promote fluent activities and consolidate reliable identity.

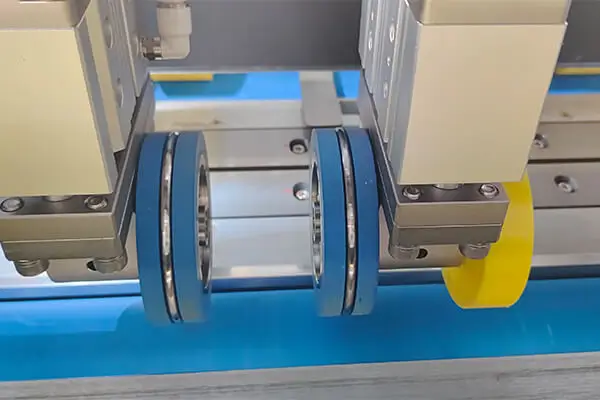

At outset, consider your operational systems. Study current machinery and staff to find possible constraints or segments requiring optimization. Then, consider methods for enhancing your output volume. Contemplate acquiring fresh apparatus or enhancing present devices to amplify productivity.

Note that amplifying output is less important than refining entire operation. Employ agile production models to cut waste and maximize input use. Improve procedures, robotize routine functions, and dedicate to employee coaching to establish a skilled workforce.

At last, establish solid rapport with distributors to assure regular input streams. Applying these plans, you will competently raise box creation and meet surging purchaser expectations.

Advancements in Corrugated Technology

The packaging industry is constantly evolving, driven by the need for sustainable, efficient, and innovative solutions. Corrugated carton board, a dependable material for ages, undergoes resurgence fueled by pioneering developments. From sturdy frameworks to connected components, corrugated sheets accept future technologies. Producers investigate fresh methods to optimize carton functionality, integrating sustainable substances and techniques. The product is a flow of fresh packaging designs remolding the trade setting.

These advancements resolve important issues confronting companies, like lowering discard and improving supply chains. Patrons correspondingly profit from these improvements, acquiring cartons that are firmer and more user-centric. The outlook for corrugated materials is promising, rich with possibilities for greener and more effective packaging systems.

Eco-Conscious Corrugated Packaging: Sustainable Selections

Corrugated parcels form a key part of modern transportation chains. Usually created from stock, such packages carry important implications for habitats. Even so, heightened appreciation for eco-conscious strategies involves producing parcel goods. Thankfully, cutting-edge methods are present to elevate eco-friendly traits of such shipments.

A vital component embraces applying recycled pulp. By incorporating production or customer discards, the desire for untouched fibers declines, conserving woodlands and environmental assets.

Also, fabricators engage in eco-conscious processing strategies. This involves enhancing power usage and minimizing refuse across distribution networks. Consumers have a part by buying packages recognized as eco-conscious. Find symbols like Forest Stewardship Council or Sustainable Forestry Initiative, guaranteeing ethical material use and production.

Via integrating these strategies, we maintain boxes as fundamental trade features while curbing ecological harm.

Securing Premium Corrugated Case Production

Attaining superior output in container fabrication relies on careful quality assurance steps. Launching with resource gathering and wrapping with final check, every phase needs unrelenting watchfulness. Rigorous standards apply across fabrication to confirm every container conforms to prime benchmarks.

- Reviewing initial supplies for blemishes, endurance, and conformity is fundamental to averting later setbacks.

- Maintaining exact measurements and allowances in shaping and bending guarantees cartons are mechanically stable and suitable for purpose.

- Consistent evaluation of design application maintains bright imagery and readable letters

- Utilizing machine-driven monitoring solutions enhances workflow and exactness in inspection tasks

By valuing quality oversight at each step, builders produce parcels that are resilient and visually striking. This emphasis on excellence pleases customer needs and enhances corporate reputation.

Packaging Printing: Labeling and Effect

Carton design printing plays a key role in brand recognition. When consumers encounter your product, the box itself becomes a valuable opportunity for making an impression. A professionally composed print on packaging can fascinate buyers, display brand traits, and raise purchase intentions.

Likewise, box printing delivers assorted options to modify your cartons. With bold hues to creative patterns, you may express brand character via the form of packaging.

Ultimately, corrugated box printing is more than just a functional necessity – it's a powerful means to strengthen your brand presence and connect with your audience.

From Primary Inputs to Completed Items: The Corrugated Container Route

The manufacturing of a corrugated box is a fascinating process that transforms simple raw materials into a vital shipping and packaging solution. The process initiates by acquiring pulp, often sourced from reused stock. Thereafter, pulp turns into panels of corrugated pulpboard, with a ridged center enclosed by two smooth liners.

These panels are carefully shaped per exact requirements, then joined with dedicated equipment to form the intended carton outline. Glues serve a key function in bonding pieces firmly, providing a sturdy and resilient configuration.

To finish, parcels undergo comprehensive assessment protocols to validate stability and conformity to industry benchmarks.

Coming from straightforward foundations, the shipment materializes as a durable packaging creation, intended to protect many goods throughout shipment.

Global Container Market: Movements and Chances

The global corrugated box market is corrugated box maker experiencing a period of growth. This flourishing business is energized by escalating buyer expectations for packaging. Essential elements include advancement of online marketplace and desire for eco-conscious packaging